Lockout Tagout Management | A Key Element for Health & Safety

The Smart Lockout Tagout Software (LOTO) That Keeps Operations Running

Lockout Tagout

More Efficiency, Control, Safety, Compliance

Less Improvisation, Downtimes, Mistakes, Near Misses

The Industry Reference for Your Lockout Tagout Program

Enroll your teams with smart, easy-to-use software and keep Energy Control Procedures up to date with approval workflows.

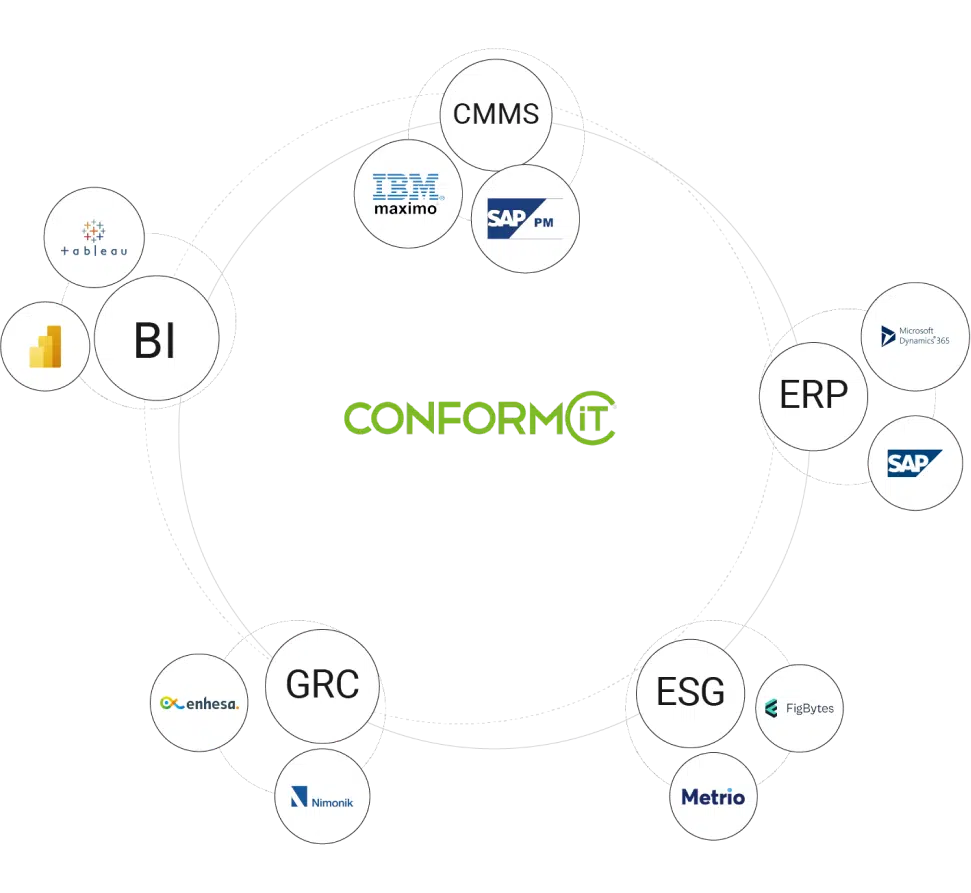

Streamline maintenance workflows by integrating CMMS and putting accurate data at the fingertips of frontline workers.

Standardize information according to OSHA requirements and demonstrate due diligence through a complete history of changes and LOTO activities.

Everything You Need for LOTO Peace of Mind

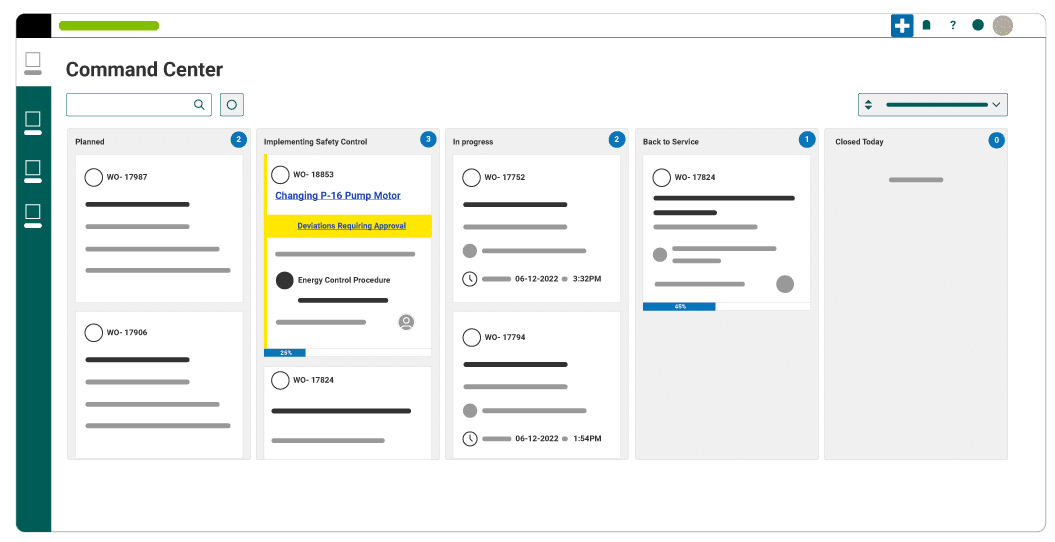

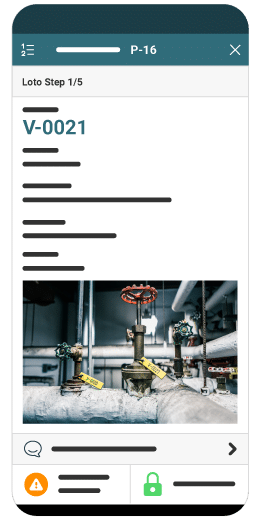

Configure roles to prevent mistakes and reference lists to standardize text. Quickly update procedures and enrich ECP with P&IDs, SOPs, and images.

Use the CONFORMiT.ai app from anywhere (even offline) to gain visibility on every Lockout activity. Implement an Energy Control Procedure (ECP) with step-by-step workflows and instructions.

A platform structured around your assets, isolation devices and workflows to keep data current across LOTO sheets. Grow worker confidence in your program.

Access your digital Lockout station in real-time. Analyze and approve every deviation. View rich dashboards about your Control of Work system.

What our users say

Streamline Maintenance Planning

& Activities With Smart Integrations

And more!

Q&A

Lockout Tagout