What is Safe Work Procedure (SWP) software?

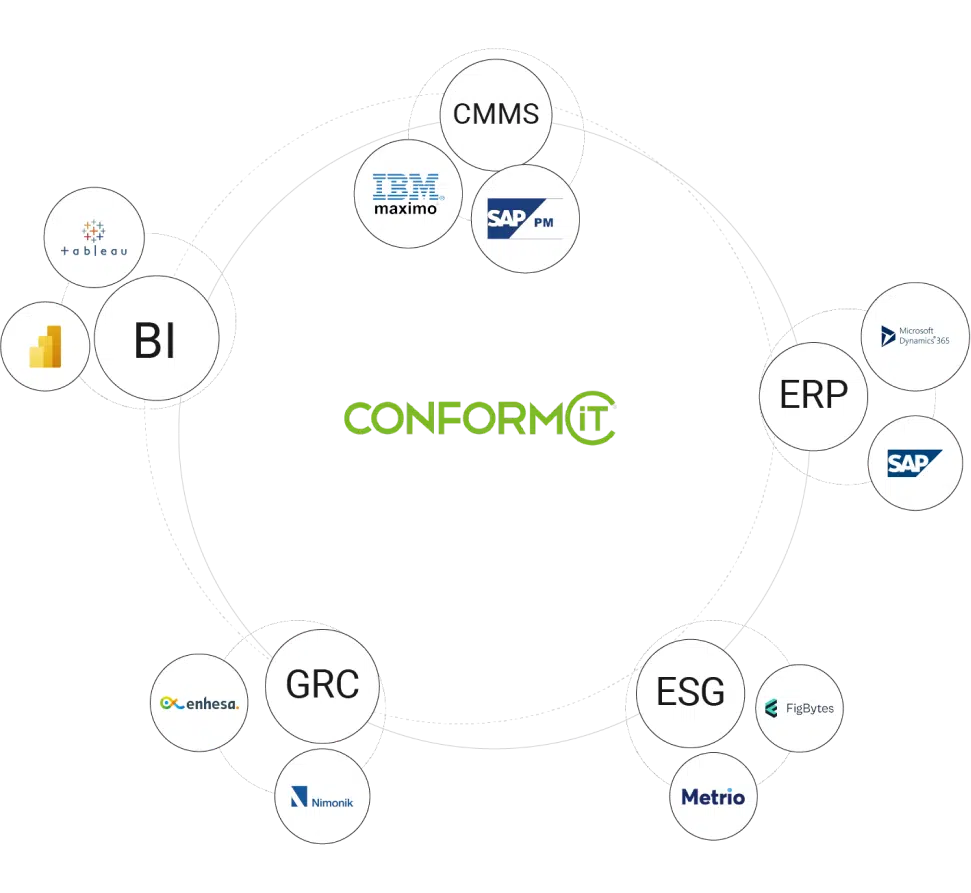

Safe Work Procedure (SWP) software—also known as digital SOP management, Safety Operating Procedures (SOP), electronic SOP system, Standard Work Procedure, or workplace safety software—is a cloud-based solution that enables safety managers, maintenance supervisors, and EHS (Environmental, Health, and Safety) professionals to create, publish, and maintain digital step-by-step safety instructions. By using Safety Operating Procedure software like CONFORMiT, organizations can:

Standardize Safety Processes Across All Sites | Implement consistent Safety Operating Procedure templates and digital SOP checklists for high-risk tasks, ensuring every worker follows approved safety steps every time.

Ensure Regulatory Compliance and OSHA Readiness | Align with OSHA, ISO 45001, ANSI, and other industry standards by embedding hazard analysis, risk assessments, and audit-ready records directly into each SOP.

Improve Accessibility with Mobile & Desktop Access | Provide on-demand access to electronic SOPs and digital safety checklists via tablets or smartphones—ideal for industries like mining, pulp and paper, chemicals, and oil & gas.

Automate Version Control and Change Tracking | Keep your electronic SOP library up to date with automatic version control, audit trails, and revision history so you always have the latest, approved procedure in place.

Streamline EHS Reporting and Analytics | Leverage integrated reporting dashboards and safety analytics to track SOP completion rates, identify common non-compliance trends, and continuously improve your safety management system.

By adopting Operational Safety Procedures software, companies reduce workplace incidents, lower operational risk, and boost productivity by making it easy for teams to follow safe practices every time.

What types of tasks require a Safe Work Procedure solution?

A Safety Operating Procedure (SOP) solution is critical for any high-risk activity where there is potential for serious injury, regulatory violation, or operational shutdown. Industries that rely on SOP software include mining, pulp and paper, metals & mining, oil & gas, chemical processing, and utilities. Common tasks that demand a digital SOP or SOP management system include:

Lockout/Tagout (LOTO) and Energy Isolation | Implement electronic LOTO procedures and energy control checklists to ensure machinery is fully de-energized and tagged out before maintenance or repair—reducing electrical shock, arc flash, and mechanical hazards.

Confined Space Entry and Rescue | Use a step-by-step confined space entry SOP template with hazard assessment, air monitoring requirements, and rescue plans to mitigate risks like asphyxiation, toxic exposure, or engulfment.

Working at Heights and Fall Protection | Deploy a digital elevated work platform SOP (e.g., scaffolding, mobile elevating work platforms, tower work) with fall protection checklists, PPE specifications, and rescue procedures.

Hot Work and Fire Prevention | Create standardized hot work SOPs (welding, cutting, brazing) with fire watch requirements, fire extinguisher locations, and atmospheric testing steps to prevent fires and explosions.

Hazardous Chemical Handling and Storage | Develop chemical handling SOPs, including hazardous material identification, PPE requirements, spill response, and waste disposal protocols—ensuring compliance with GHS labeling and MSDS/SDS documentation.

Heavy Machinery and Equipment Operation | Establish equipment-specific SOPs for forklifts, crushers, presses, and conveyors with pre-start inspections, operating parameters, and emergency shutdown procedures.

Electrical Maintenance and Testing | Generate an electrical work SOP that covers lockout, voltage testing, PPE selection (e.g., arc-flash rated gear), and clearance procedures to prevent electrocution or arc flash incidents.

Using a digital SOP solution like CONFORMiT ensures each of these high-risk tasks is performed consistently—with embedded risk assessments, digital sign-offs, and real-time compliance tracking.

What type of information is captured by Safe Work Procedure software?

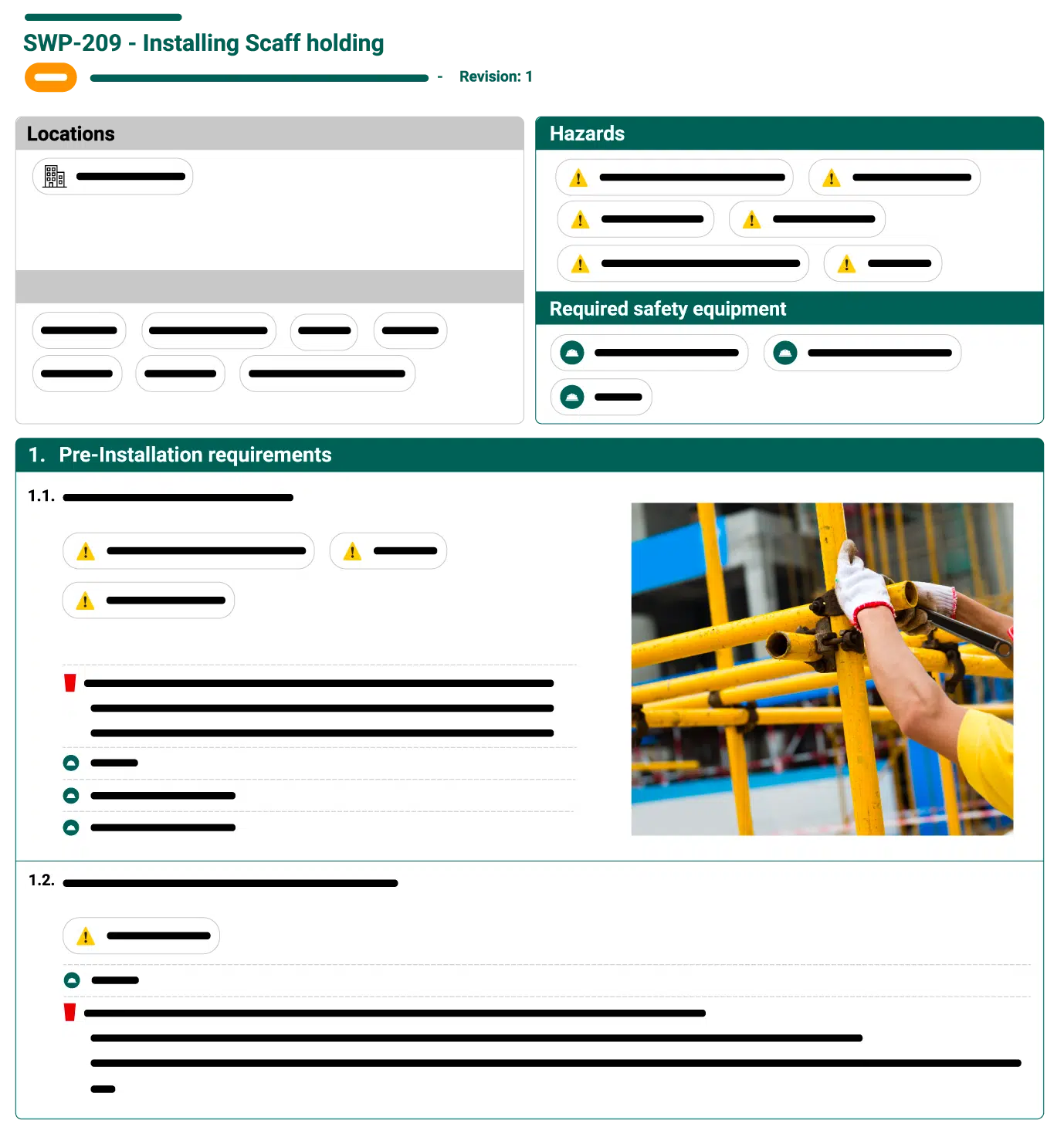

Safety Operating Procedure (SOP) software captures all the essential data your EHS team needs to manage risk, ensure compliance, and drive continuous improvement. Key information fields typically include:

Task Name & Detailed Description | Define the job or activity with a clear title and scope that identifies exactly what work is being performed and under what conditions.

Step-by-Step Instructions & Digital SOP Templates | Break down each task into sequential steps, from pre-start equipment checks to shutdown procedures—often with embedded photos, diagrams, or videos for added clarity.

Hazard Identification & Risk Assessment | List identified hazards (e.g., pinch points, chemical exposure, fall hazards) and include a risk matrix alongside critical control measures, such as engineering controls or administrative controls.

Required Controls & PPE Requirements | Specify personal protective equipment (PPE), lockout/tagout devices, gas detection monitors, fall protection harnesses, or any specialized tool or device needed for safe completion.

Roles, Responsibilities & Competency Requirements | Assign authorized personnel, designate responsible supervisors or permit issuers, and capture any required certifications or training prerequisites (e.g., confined space certification, forklift operator license).

Emergency Response Procedures & Rescue Plans | Embed emergency SOPs detailing what to do if an incident occurs—first aid steps, spill containment, fire response, or confined space rescue—along with contact information for EHS coordinators.

Regulatory References & Compliance Links | Link to relevant OSHA standards (e.g., 29 CFR 1910.147 for LOTO), ISO 45001 clauses, local environmental regulations, and internal company policies to ensure alignment.

Approval Workflows & Electronic Signatures | Track the review and approval process with digital sign-off by subject matter experts (SMEs), safety managers, or department heads prior to publishing any new or revised SOP.

Version Control, Revision History & Audit Trail | Maintain an audit-ready record of changes, including who edited the SOP, what edits were made, and when they were approved—ideal for safety audits and compliance inspections.

Training & Competency Records | Integrate with learning management systems (LMS) to automatically assign SOP-based training modules and track worker sign-offs, ensuring only qualified personnel execute critical tasks.

By centralizing this information in a user-friendly interface, CONFORMiT’s Safe Work Procedures software becomes a single source of truth for your SOP library. This enables safety teams to conduct real-time audits, generate automated compliance reports, and continuously improve safety workflows—ultimately reducing incidents and boosting operational efficiency.

What’s the difference between Job Safety Analysis (JSA) and Safe Work Procedure (SWP)?

While both Job Safety Analysis (JSA) and Safe Work Procedure (Safety Operating Procedure (SOP)) are critical tools for workplace safety, they serve different—but complementary—purposes:

Job Safety Analysis (JSA) | Also known as Job Hazard Analysis (JHA), a JSA is a risk assessment tool used to identify the specific hazards associated with a job or task before it is performed. It breaks the job into steps, analyzes potential risks for each step, and outlines controls or preventive measures to reduce those risks.

Purpose | To proactively identify hazards and reduce risk through tailored mitigation strategies.

Key Elements |

Job steps and associated hazards

Risk level or likelihood/severity rating

Controls (engineering, administrative, PPE)

Typically completed before non-routine or high-risk work

Safety Operating Procedure (SOP) | An SOP is a step-by-step instruction guide that tells workers how to safely perform a task. It includes clear operational steps, safety controls, required PPE, and emergency procedures. Unlike a JSA, an SOP is a standardized reference document used repeatedly for similar tasks.

Purpose | To ensure consistent and safe task execution through formalized procedures.

Key Elements |

Task description

Step-by-step instructions

Embedded safety controls and required PPE

Roles/responsibilities and emergency actions

At CONFORMiT, our EHS software supports both JSA and Safe Operating Procedures creation—allowing safety managers to assess risks and operationalize safe work practices in one connected platform. This ensures that hazard identification (JSA) leads directly into structured execution (SOP), helping teams reduce incidents and maintain compliance across all levels of operation.