CONFORMiT Introduces Digital Safe Operating Procedures for Smarter Work

Does your inspection process allow you to work efficiently and focus on what matters?

9 January 2024

Inspection rounds are essential and important for organizations, for a number of reasons:

However, inspection rounds eat up valuable time and unfortunately can give the impression that they don’t really add any value. Is this what you experience too? I’d like to suggest a few areas for improvement to help you work on the right things.

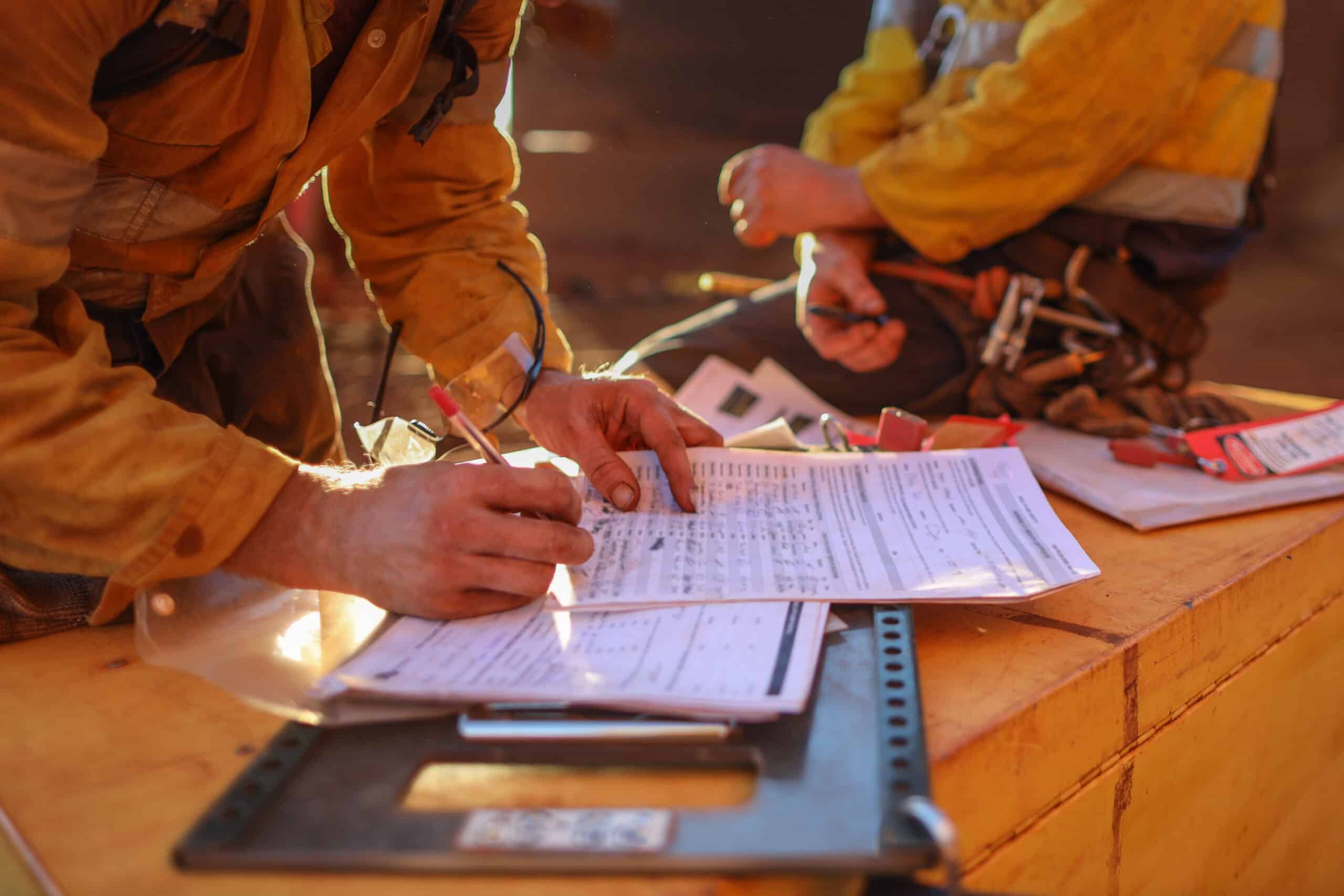

If you’re still working on paper forms, you could save precious time with the help of technology (which, by the way, is increasingly affordable). Digitization will enable you to :

The design of inspection templates rarely offers the possibility of specifying expectations and requirements for an item to be inspected, which can generate non-conformities that aren’t there, and even worse, omit those that really are because they remain undetected. Which raises the following question: Do you really have the time to work on non-conformities that aren’t there, and the luxury of letting real non-conformities slip through the cracks? Certainly not! So, how do you ensure a more effective detection of non-conformities? Certainly not with a paper document with a ton of lines and boxes written in small print.

Digitization makes it possible to give details of the requirements for an inspection point, thus minimizing subjectivity. Here’s an example. You need to inspect a mechanic shop for good order. What does “good order in your organization” mean? It probably means that :

The digitization of inspection forms makes it possible to add details of expectations with regard to an operational requirement. This enables better visualization of compliant items and improved detection of non-conformities.

Organizations not using CAPA digitization frequently rely on one or a few people to update CAPA inventories. It’s a laborious task, and one that doesn’t make employees accountable for the progress of CAPAs. There’s no need to ask how much time is spent on updating and producing performance indicators for this process.

If your process is paper-based, it’s quite possible that you can’t easily extract performance data (KPIs) from your inspections for your sector or your organization as a whole. If you do, you’ll probably have to go through substantial quantities of paper documents and account for it all in a spreadsheet of some kind.

A small study among our customers enabled us to estimate that digitizing the process could reasonably (and conservatively) reduce the management of an inspection by 2.5 hours per inspection.

If your inspections give you headaches, let us help, so that you can get on with what matters most.